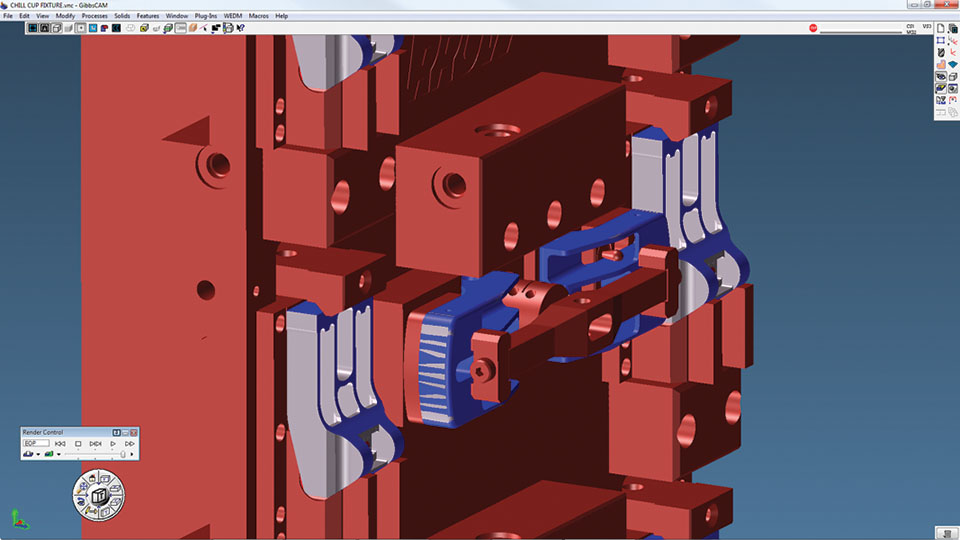

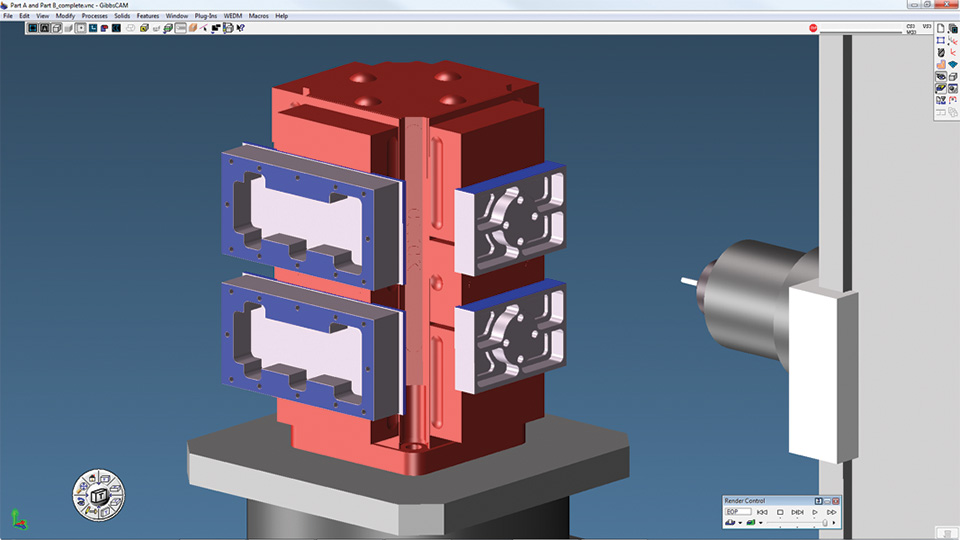

GibbsCAM TMS (Tombstone Management System) was developed specifically to simplify and streamline the multi-part setup, programming, toolpath verification and post processing for tombstone machining. Within a single interactive graphic interface, the TMS dialog provides all the options and flexibility required for CNC programmers to specify and modify machining strategies and generate efficient, error-free G-code ready for your machines.

GibbsCAM TMS provides:

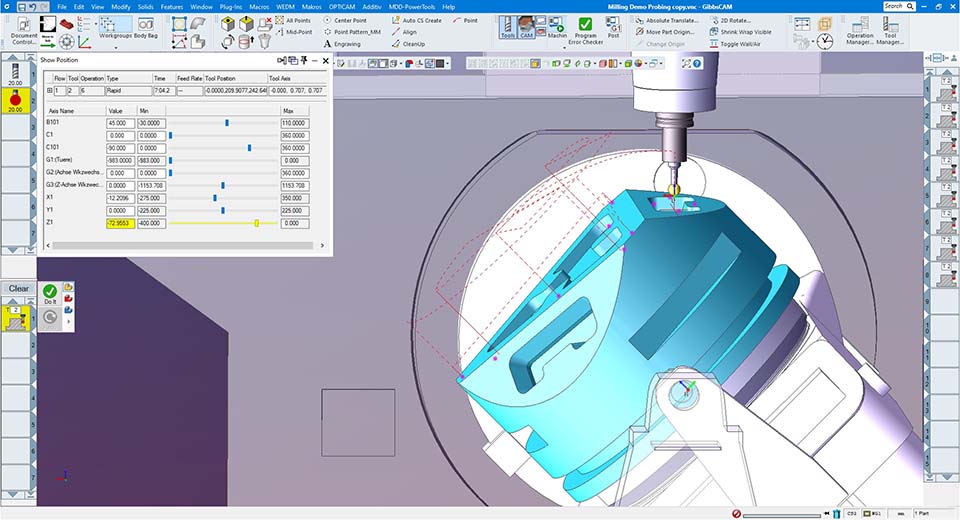

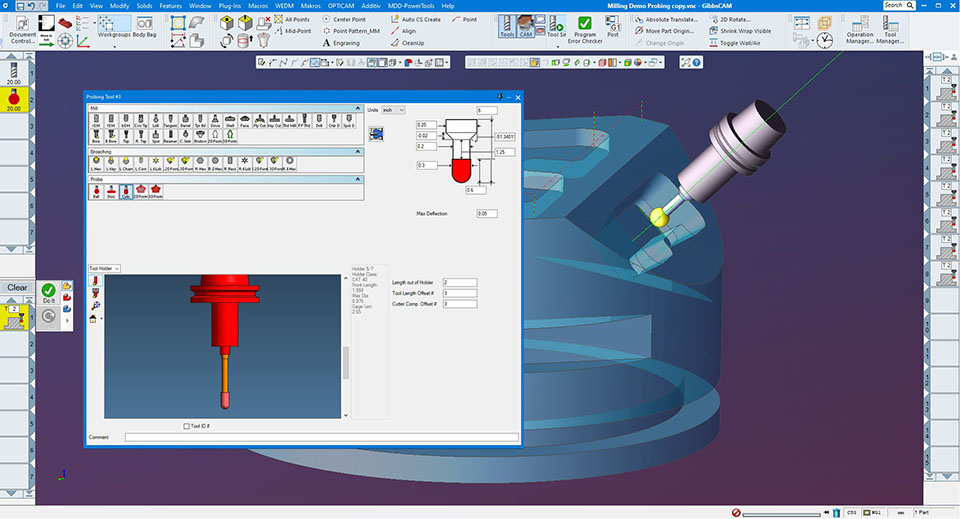

GibbsCAM in process Probing gives you access to on machine inspection, within the easy-to-use GibbsCAM programming environment. On-machine probing saves you time and money. Probing for workpiece starting positions enables improved automation and reduces human error by automatically establishing datums and setting work fixture offets (WFOs). In-process inspection identifies problems early, avoiding scrapped parts and reducing wasted machine time. Finished feature probing gives you confidence in your parts and documented conformance records.

GibbsCAM Probing supports a wide variety of industry-standard probing modules and styluses, including ball, disc, cylinder, and user-defined form stylus tips. To prevent damage to your probes, maximum deflection can be specified, and any transition moves which deflect the probe by more than the maximum amount will be automatically detected as collisions.

Download Brochure