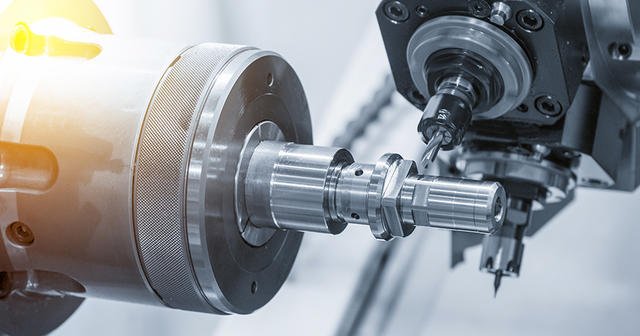

GibbsCAM® is cutting-edge CAM software for programming CNC machine tools with the power and flexibility to make parts the way you want.

Simple, fast, versatile, sustainable and reliable

Program all your cutting machines with just one software solution - from simple automatic lathes to complex, multi-channel turn-mill centers and sliding headstock lathes. GibbsCAM pays off! With us…

Many companies today invest in high-quality, complex machines. The problem is that programming them to reach their full potential is out of reach, and the company can't remain globally competitive.

A flexible CAM software is especially critical if you manufacture geometrically-demanding parts in medium to high quantities, or multi-channel mill-turn centers (multi-task machines, MTM) or sliding headstock lathes. You need a solution that fully masters the complexity of the machine and grows with your requirements.

GibbsCAM has the necessary know-how to provide a powerful CNC solution that is easy for everyone to use, and empowers machines to manufacture even the most complicated parts quickly, precisely and reliably.

Increase productivity - GibbsCAM is easy to learn and intuitive to use for everyone in your organization. Fast programming for experienced programmers and quick learning for new users, which results up to 75% faster programming speed. GibbsCAM allows you to exploit the full potential of your machine.

Maximize profits - Thanks to features such as high-speed machining strategies, precise machine simulation for the most complex machines and toolpath simulation with collision detection, GibbsCAM enables you to achieve greater efficiency, accuracy and reliability in part production. This saves valuable time for testing and checking programs. Your cycle times are reduced, your scrap is minimized, you can deliver more parts, and generate more sales.

Be future-proof - With the ever-increasing irregularity and complexity of machinery, the demands on programmers and users are also increasing. With GibbsCAM, you are able to program all your cutting machines with just one software solution - regardless of the machine manufacturer, from simple to complex, today and in the future. GibbsCAM simply grows with you by expanding its functionality as required.

From Citizen, DMG Mori, and Index to Mazak, OKUMA, Star, Tornos, and Willemin, we support all leading machine tool manufacturers. Whether lathes, milling machines, turn-mill centers, multi-spindle machines, complex multi-channel machining centers, or sliding headstock lathes, with GibbsCAM you can program any CNC machine. Detailed information can be found in the list of our machine partners.

I wholeheartedly recommend GibbsCAM to anyone investing in multi-channel turn-mill centers or upgrading their current software. Thanks to GibbsCAM, we are more efficient and can produce parts that we could never produce before.