Looking to make your already efficient and reliable GibbsCAM machining even faster?

Optimizer for GibbsCAM takes your NC programs to the next level by dynamically adjusting feed rates during cutting. This ensures maximum and consistent chip thickness, resulting in faster cycle times, improved tool life, and more efficient machining.

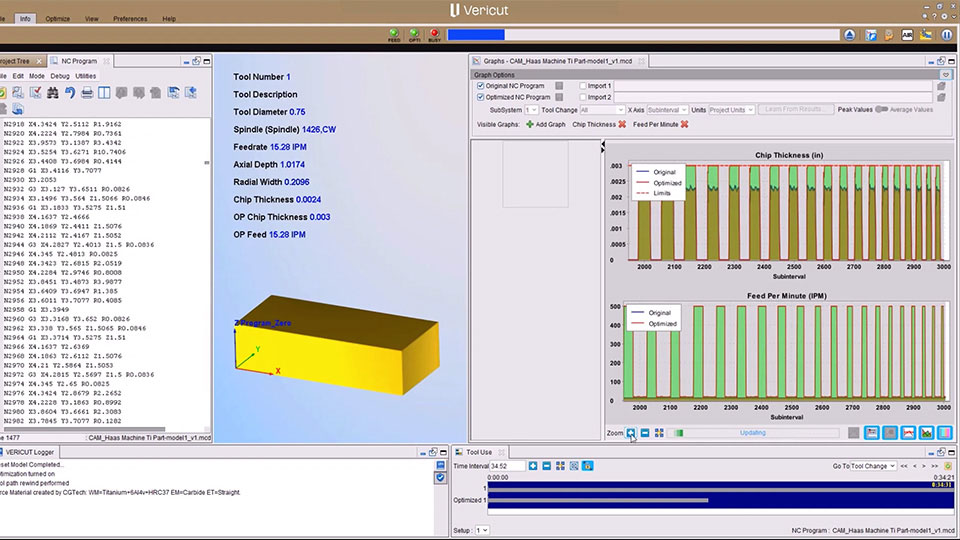

Download BrochureIn CNC machining, maintaining the ideal maximum chip thickness is critical to achieving both productivity and process reliability. Optimal cutting performance only occurs when chip thickness is precisely matched to the material and cutting tool. Too little, and the tool may rub instead of cut; too much, and you risk tool overload or breakage. Striking this balance requires accurate control of the NC program, spindle speed, and—most importantly—feed rates.

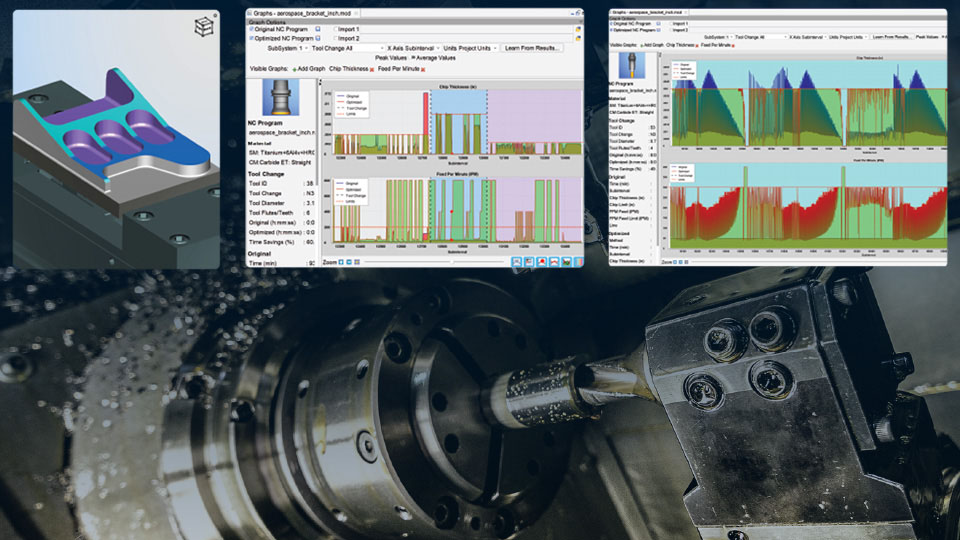

Optimizer for GibbsCAM takes your NC program to the next level by performing a detailed, block-by-block analysis of each cut. It evaluates the interaction between the cutting tool and stock material, then automatically adjusts feed rates to maintain a consistent and optimal chip thickness, while also managing cutting forces, power consumption, and tool deflection as needed.

This intelligent process, known as feed rate scheduling, ensures maximum efficiency and tool performance. The result is an optimized NC program ready for the machine, delivering shorter cycle times, longer tool life, and superior cutting consistency.

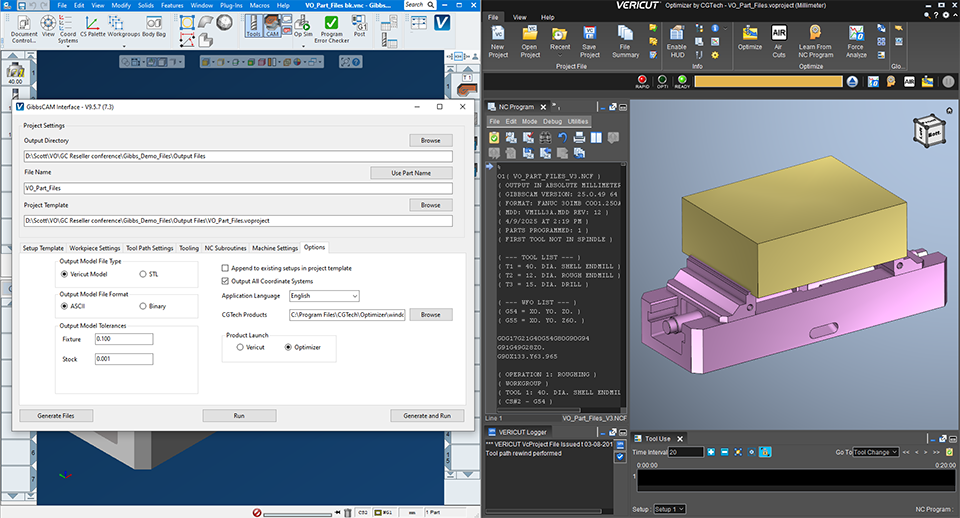

Seamlessly bridge GibbsCAM and Optimizer with direct data transfer of Stock Model, Fixture Model, Cutting Tools, and NC Program from within the familiar GibbsCAM interface.