一个界面,多种用途,GibbsCAM与您一起成长。

GibbsCAM被整合成为一个单一的应用程序。当你添加不同选项时,你不会被迫学习一个新的界面。相反,所有的选项都集成在熟悉的、用户友好的界面中。该软件根据您的初始要求进行配置,并随着您的需求增长而扩展。通过这种方式我们保护你在软件和培训方面的投资。

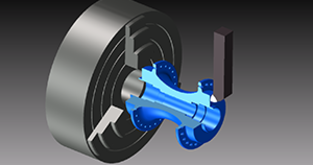

GibbsCAM产品车削支持所有两轴线框加工,具有轮廓加工、自动粗加工、多坡度和多谷度加工、切入式粗加工、螺纹加工、仿型粗加工、钻孔、攻丝和镗孔等完整功能。具有先进的功能,比如保持对当前毛坯状况的识别,使车床编程不仅简单而且非常高效。GibbsCAM产品车削软件为您的车削中心提供简单易用、功能强大的编程功能。

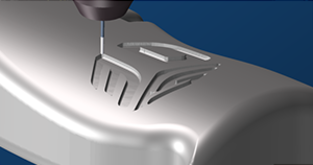

SolidSurfacer 选项包括高级曲面和实体造型功能,以及曲面加工和实体加工的高级功能。借助直观的 GibbsCAM 图形用户界面轻松使用复杂的曲面和实体功能。

缠绕加工选项驱动一个回转轴和两个线性轴来实现 3 轴刀具路径。它扩展了标准的 3 轴铣削功能,用于具有回转轴的机床,以实现包络几何、圆柱形和缠绕加工以及回转重复功能。在铣削时,回转通常围绕 A 轴或 B 轴,而在车铣复合加工时,C 轴运动代替 Y 轴运动。

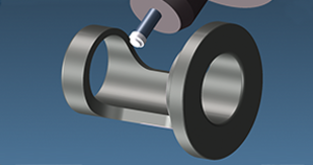

GibbsCAM 径向铣削选项驱动一个回转轴和三个线性轴来实现 4 轴刀具路径。它为偏心线 Y 轴旋转加工提供粗加工和精轧机加工,可控制壁角和刀具啮合。输入是从实体中提取的 3D 线框几何或通过其他方式创建的,以驱动和定向刀具。

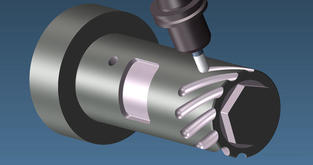

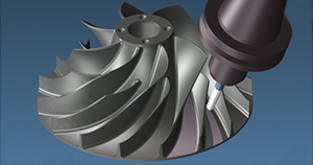

GibbsCAM 5 轴多叶片是对 GibbsCAM 5 轴铣削的补充,优化后适用于编程加工中心和多任务机床 (MTM) 以制造涡轮机械部件。它简化了带有叶片部件的加工,包括叶盘、叶环和叶轮。

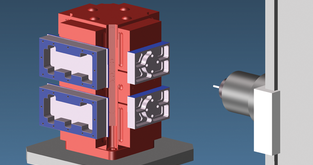

塔式加工系统 (TMS) 专门用于简化和精简多部件设置、编程、刀具路径验证和塔式加工的后处理。在一个交互式图形界面中,TMS 对话框提供了数控编程员所需的所有选项和灵活性,从而指定和修改加工策略,并为机床生成高效、无误的 G 代码。

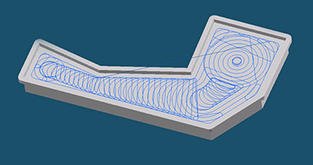

VoluMill™ for GibbsCAM 是一种超高性能的刀具路径 (UHPT) 选项,使用连续高速的刀具路径生成优化的数控程序。这些强大、高速、高材料去除率功能可以帮助您为车间中的各种铣削部件类型创建最快、最有效的刀具路径。