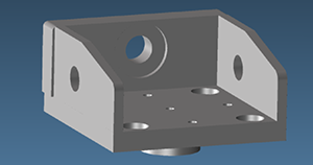

GibbsCAM’s full range of milling options provides you with the power and flexibility to program all your CNC mills with a single program and a single interface. GibbsCAM gives you the freedom to make your parts, your way

Download Milling, Turning, and Mill-Turn Datasheet

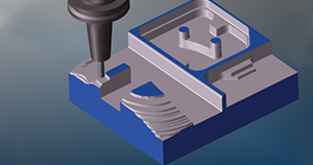

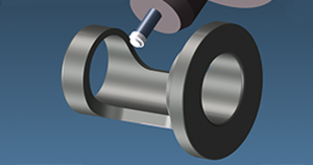

GibbsCAM Production Milling delivers an easy-to-use CNC programming solution for shops that are cutting 2-axis features such as pockets, holes, and slots.

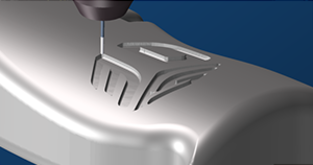

GibbsCAM 3-Axis milling creates smooth, accurate tool paths for cutting complex shapes using either surfaces, solid models, or any combination of both.

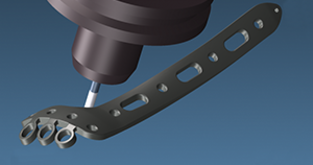

GibbsCAM Multi-Axis milling uses state of the art toolpath strategies to generate accurate, reliable G-code for 4 and 5-Axis CNC machining centers.

One interface. Multiple uses. GibbsCAM grows with you.

GibbsCAM is organized as a single application. When you add options, you are not forced to learn a new interface. Instead, all options are integrated into the familiar, user-friendly interface. The software is configured for your initial requirements and expanded as your needs grow. We protect your investment in both software and training.

GibbsCAM Production Milling supports 2-axis through simple 3-axis wireframe machining with full functionality for contouring, pocketing with unlimited bosses/islands, thread milling, face milling, 2D/3D spiral creation, drilling with support for many drill cycles, tapping, and boring.

The Solids Import option provides entry-level support to machine solid models. Solid models can be read, viewed, and manipulated. You can select and extract geometry for machining.

GibbsCAM 2.5D Solids includes significant surface and solid modeling capabilities and the functionality to machine surfaces and solids directly. Create, import, and modify solid models and then generate programs to machine them.

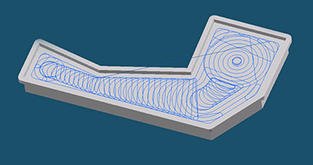

VoluMill™ for GibbsCAM is an ultra-high performance toolpath (UHPT) option that uses a continuous, high-speed toolpath for an optimized CNC program.

An extension to the GibbsCAM integrated Cut Part Rendering visualization/verification capability, Machine Simulation uses animated machine tool models to identify any program errors before they cause costly mistakes on the shop floor.

The SolidSurfacer option includes high-level surface and solids modeling capabilities and advanced functionality for machining surfaces and solids. Complex surface and solid functions are made easy with the intuitive GibbsCAM graphical user interface.

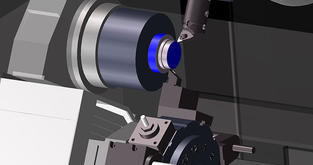

The GibbsCAM Rotary Milling option drives one rotary and three linear axes to achieve a 4-axis toolpath. It provides a roughing and a finishing mill process for off-centerline Y-axis rotary machining for control of wall angles and tool engagement.

The Polar and Cylindrical Milling option drives one rotary and two linear axes to achieve a 3-axis toolpath. It extends the standard 3-axis milling functions for use on machines with a rotary axis to enable wrapped geometry, cylindrical and polar rotary milling, and rotary repeats.

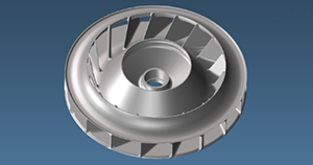

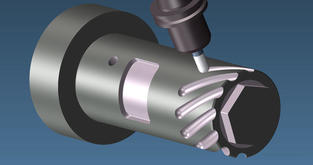

The GibbsCAM 5-axis option supports simultaneous 4- and 5-axis machining with various tool types. In combination with GibbsCAM MTM, it also supports sophisticated multi-task machines with live tooling on articulated heads.

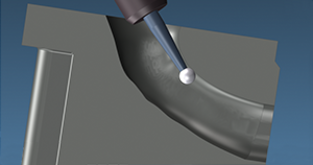

An addition to GibbsCAM 5-Axis Milling, 5-Axis Porting is optimized to simplify machining ports, manifolds, throttle bodies, and any tubular openings that change shape and curvature from end to end.

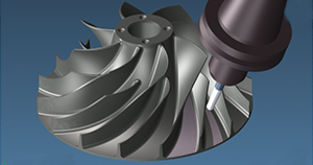

An addition to GibbsCAM 5-Axis Milling, GibbsCAM 5-Axis MultiBlade is optimized for programming machining centers and multi-tasking machines (MTMs) to make turbomachinery parts.

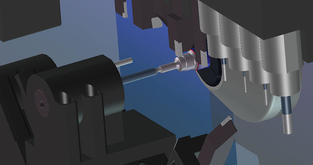

Specifically designed to address the CNC programming requirements of complex, multi-task machining (MTM) tools, GibbsCAM MTM gives you powerful programming tools that are easy to learn and use with the ultimate in flexibility.

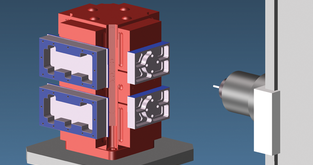

The Tombstone Management System (TMS) was developed specifically to simplify and streamline the multi-part setup, programming, toolpath verification, and post processing for tombstone machining.

Choose from three base packages:

Then add software maintenance and options as needed. Because all options are integrated into a single interface, you don’t need to learn a new program, which saves time and training costs.

In addition, GibbsCAM offers a 30-day, money-back guarantee.