The global initiative toward green energy has opened doors for entrepreneurs, spawned new companies, and provided opportunities for manufacturing companies looking for growth. However, not every manufacturer has had the expertise required to take advantage of the new opportunities. Nevertheless, when a new technology requires components similar to those already used in other applications, a good marriage is possible. Such is the case with a new solar project and a company that has been serving the energy industry for more than one hundred years.

Taylor Forge Engineered Systems, a unique design and manufacturing organization, has traditionally served the petroleum, natural gas, and nuclear power industries with three manufacturing facilities in Kansas. The company uses proprietary processes, and some CNC machine tools to manufacture parts from carbon steels and super alloys, typically Inconel – a tough nickel chromium alloy known for its anti-oxidation and anti-corrosive properties under heat and pressure.

In late 2011, the company found an opportunity to enter solar energy as a supplier to a power plant in production in the United States. The plant will generate more than 100 MW of electricity, using thousands of heliostats, (suntracking mirrors), to concentrate solar energy onto a tower more than 500 feet high. Solar radiation will heat and melt salt, which will circulate through pipes and headers, into storage, where the hot salt will supply heat to drive a steam generator on demand.

Taylor Forge, equipped to create cylindrical pressure and containment vessels from plates up to 7" thick, won the contract to manufacture the headers required by the solar power plant.

According to Manufacturing Engineer, Kirt Stevens (Paola, KS. facility), it was not long ago that Taylor Forge would not have been able to bid the project for lack of a CNC machine appropriate for high precision and a reliable utility for NC programming. Five years ago, when he started working at Taylor Forge, Stevens discovered that the company had been contracting for CNC programming services because there were no in-house programming resources.

Forging Ahead with Solar Energy Using GibbsCAM

The global initiative toward green energy has opened doors for entrepreneurs, spawned new companies, and provided opportunities for manufacturing companies looking for growth. However, not every manufacturer has had the expertise required to take advantage of the new opportunities. Nevertheless, when a new technology requires components similar to those already used in other applications, a good marriage is possible. Such is the case with a new solar project and a company that has been serving the energy industry for more than one hundred years.

Taylor Forge Engineered Systems, a unique design and manufacturing organization, has traditionally served the petroleum, natural gas, and nuclear power industries with three manufacturing facilities in Kansas. The company uses proprietary processes, and some CNC machine tools to manufacture parts from carbon steels and super alloys, typically Inconel – a tough nickel chromium alloy known for its anti-oxidation and anti-corrosive properties under heat and pressure.

In late 2011, the company found an opportunity to enter solar energy as a supplier to a power plant in production in the United States. The plant will generate more than 100 MW of electricity, using thousands of heliostats, (suntracking mirrors), to concentrate solar energy onto a tower more than 500 feet high. Solar radiation will heat and melt salt, which will circulate through pipes and headers, into storage, where the hot salt will supply heat to drive a steam generator on demand.

Taylor Forge, equipped to create cylindrical pressure and containment vessels from plates up to 7" thick, won the contract to manufacture the headers required by the solar power plant.

According to Manufacturing Engineer, Kirt Stevens (Paola, KS. facility), it was not long ago that Taylor Forge would not have been able to bid the project for lack of a CNC machine appropriate for high precision and a reliable utility for NC programming. Five years ago, when he started working at Taylor Forge, Stevens discovered that the company had been contracting for CNC programming services because there were no in-house programming resources.

“Without internal expertise in programming machine tools, the company would frequently no-bid jobs or forfeit opportunities because they were unable to determine manufacturability or delivery,” Stevens explains.

Experienced with CAD, manual NC programming, and CAM systems, Stevens recognized the shortcomings immediately. However, because he needed to acclimate to new employment, and because machines were busy filling long-term contracts, he postponed any action. Nevertheless, he occasionally needed to modify NC programs to accommodate different cutting tools. However, the method used by the contractor to create programs did not lend itself to a universal command to offset for a different sized tool.

“I had to calculate the offset and manually change the coordinates of each point in the program,” Stevens notes. “Using a human as a post-processor is very risky, and it would take me eight or nine hours just to modify a program.”

Three years ago, about to begin a U.S. Government project, Stevens began his investigation into CAM systems, which included a demonstration by a customer he visited.

Stevens explains, “I asked the programmer about a specific weld bevel that, with our process at the time, would take me eight or nine hours. I watched him program it in GibbsCAM in 15 minutes, and then watched a large horizontal mill machine it in 45 minutes. I immediately saw their high level of confidence and competence with GibbsCAM.”

Stevens researched GibbsCAM and other CAM systems, choosing GibbsCAM because everything he saw and heard was positive, and acquired it in the summer of 2009. With his knowledge of machining, he was using GibbsCAM 5-Axis software the first week, without training, generating 3- and 4-axis NC programs. At the time, Taylor Forge did not have a solid modeler, so Stevens modeled everything in GibbsCAM, using the solid models for programming.

Six months later, Taylor Forge acquired Autodesk Inventor for Engineering to develop designs and create solid models of parts requiring machining. The combination of Autodesk Inventor and GibbsCAM opened opportunities, including the contract to supply pressure vessels for the new solar energy installation.

Manufacturing Challenges

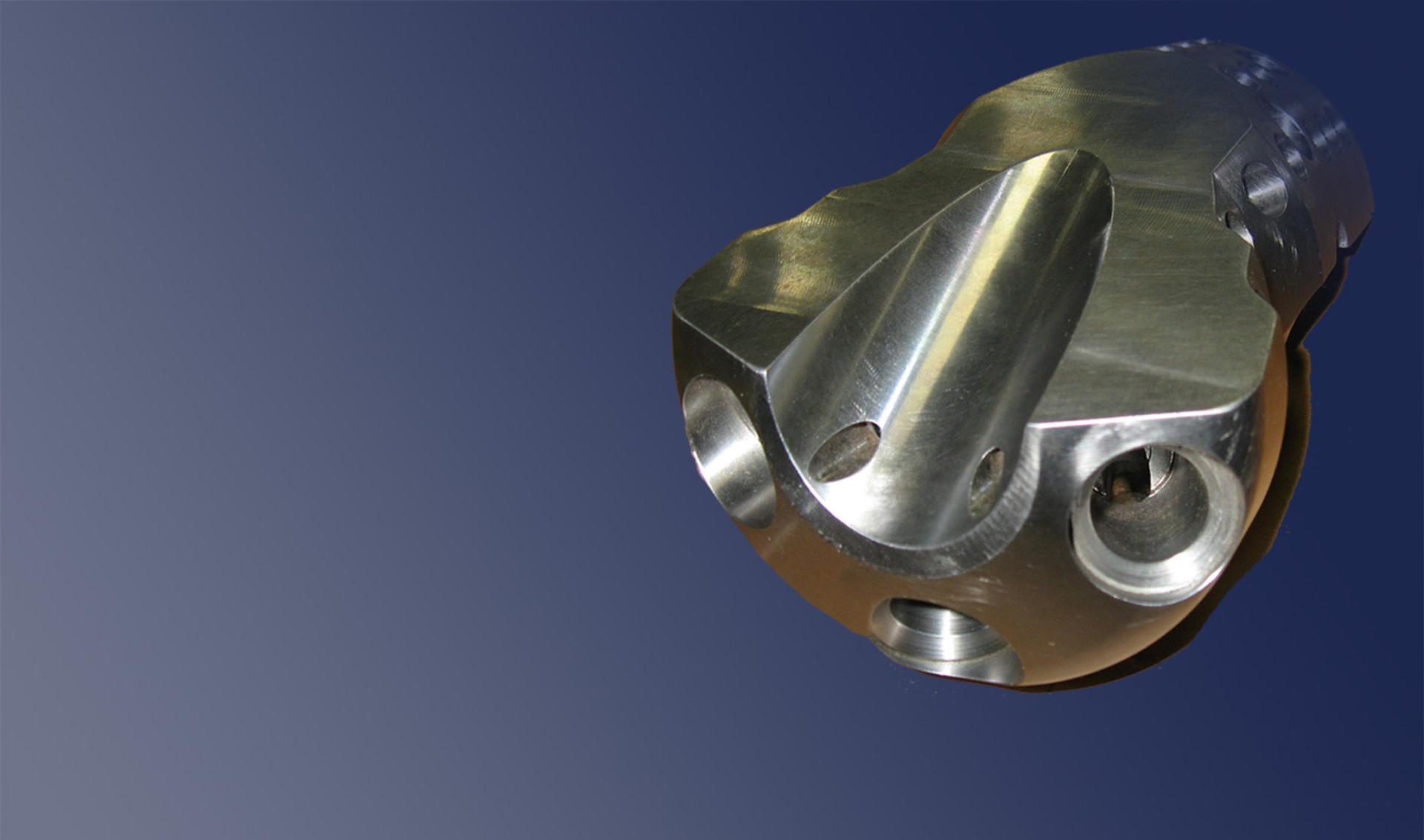

Manufacturing the headers for the solar power plant presents many challenges, even before machining begins. First, the forming operation requires rolling flat Inconel 625 plate into the required cylinder, heat-treating to relieve stresses, and machining edge bevels for welding. Finally, welding can cause cracking or bowing. Finished, the header is two feet in diameter, and 8 feet long, with a tolerance of 0.150" on straightness over its length.

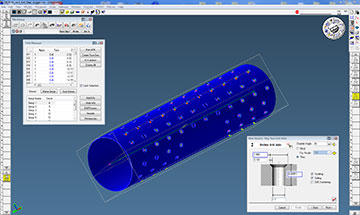

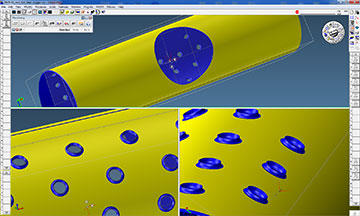

Machining the header requires boring numerous holes of small diameters at specific angles and precise locations defined by 0.100" true position tolerance from three datum. Repeatability on locations and true position tolerances required machining in a single set up. Because dedicated work on the other 4-axis machine tools are for U.S. Government contracts, Taylor Forge purchased a Haas VF11 4-axis vertical mill lathe in 2011. By then, another Manufacturing Engineer, Aaron Poe, joined the company, so purchase of a second seat of GibbsCAM occurred.

“Of all the challenges in making these headers, what is really critical is having a CAM system that is reliable, accurate, and efficient,” Stevens says. “What we do is inherently complex, and involves very expensive material – our parts frequently sell in the tens of thousands of dollars per unit, so we need something that will not create scrap. It may have taken only 20 minutes to program the holes with GibbsCAM.”

Poe adds that once the holes are bored, the header comes off the machine for more work. “Our next operation requires extrusion. With punch and die on a large press, we pull up material around each hole, and push out a shoulder to near net shape with allowance for machining.”

The header then goes back to the machine tool, where the shoulders are milled and prepared for welding.

“The milling is critical,” Poe says. “The customer will be welding Inconel tubes at each hole, so the shoulders must have a tight wall thickness tolerance of ±0.003", and consistent land and welding bevels, so there are no thick and thin areas. The welding process requires consistency from hole to hole, and from part to part to prevent welding defects. For that, the NC programming and machining have to be precise.”

For assurance, both Poe and Stevens use GibbsCAM’s Cut Part Rendering, which displays toolpath, material removal, and material condition as tools execute operations.

“We rely on it, and run all our toolpaths through it before post-processing. With the cost of our parts, it is a feature that has to be there,” Stevens says. “Post-processors are another great feature. In my experience with various CAD/CAM packages, I have been highly critical of their post-processors. In contrast, I have never had a problem with GibbsCAM post-processors for any machines.”

Adavancing Operations

Aside from enabling difficult parts, GibbsCAM has allowed Stevens to introduce machining operations that were not previously in use at Taylor Forge. Among the several examples he cites, one included his first use of GibbsCAM's helical milling routine. It was used to program threads for holes on alloy parts where tapping would not work. The machine operators, never having seen a thread hob going into a bore properly timed to create threads, were completely skeptical, and were convinced that Stevens would crash their machines. Much later, when mating parts smoothly screwed into the threads, the operators became total converts.

Stevens says that GibbsCAM has done much to improve his productivity. “In the past, just manually editing a program would take more than eight hours, but now, starting from scratch, I can model new geometry and generate reliable toolpath in two hours. In addition, the likelihood of a mistake is nearly zero,” he explains. “And, with the many toolpath variables it provides, I can shave three hours off a twelvehour process at the machine. It has saved us a tremendous amount of time.”

Poe, proficient with 3-axis programming, and without training on GibbsCAM, says the software has provided an unexpected benefit – more business.

“Sales traffic through the programming and machining area has never been higher,” he explains. “GibbsCAM has allowed us to quote many more jobs. In the past, we did not know how to do some things, or did not know if we could do them without 4-axis and NC programming, so the shop was seldom approached for a quote. Now, we are unrestricted in programming. GibbsCAM and 4-axis allow us do things, and do them the way we want. It put us in the realm of ‘we can make whatever you want.’ Now, the sales representatives come to us, and say, ‘Let’s quote this’ or ‘Are you comfortable with this?’”

As they complete the solar header contract, Stevens and Poe look forward to more projects, confident they can now meet any NC programming or machining challenge. (So far, the worst case on machining the holes with 0.100" true position tolerance from three datum has been 0.007" from nominal.)

Poe summarizes: “A good CAD modeler, a good CAM package, a 4-axis machine, and on-machine probing strain gage are all the tools we need to have the flexibility to make anything. The combination of software and machines is priceless. Whether it is from Inventor or GibbsCAM – they work extremely well together – there is no restriction. Now, our only limiting factor is machine availability.”

As seen in Today's Energy Solutions