How Wallåkra Mekaniska uses smart manufacturing and AI to increase efficiency and sustainability

Download Article PDFSwedish company Wallåkra Mekaniska, a small family-owned business, is showing how practical innovation and sustainability can go hand in hand in modern manufacturing.

With a focus on digital tools and data-driven improvements, Wallåkra has found ways to streamline operations, reduce energy use, and stay competitive in a changing industry.

So many things are evolving right now. It’s important to stay ahead of the curve. Otherwise it will be a very long distance to adapt to what’s coming.

A smarter way to program

At Wallåkra Mekaniska, programming is a key part of the production process. In the past, machines would sometimes sit idle while waiting for programs to be made. This slowed down production and affected profitability. To improve this, Wallåkra uses GibbsCAM, a CAM software they have relied on for over 14 years.

“Even new employees can quickly grasp the basics of GibbsCAM,” says Peter Strömberg, Owner of Wallåkra Mekaniska. “It’s easy to use, and our operators find the programs simple to read and understand.”

To save time on routine tasks, Wallåkra has also tested Up2Parts, an AI-based tool that helps generate programming drafts. This allows experienced programmers to focus on more complex operations and fine-tuning.

When we have to do programming, it usually means that our machines sometimes stand still and our investments are not currently making money. We’re trying to explore new tools to make that more efficient.

Using AI and automation to improve workflow

Wallåkra’s approach reflects a broader shift in manufacturing toward digitalization.

“From Sandvik’s perspective, we see that digitalization and AI technology is really transforming the industry right now. Therefore, we have spent a lot of time implementing the first level of AI solutions in some of our solutions and we have seen that this as a used potential to help the customers be an even more efficient.” Says Fredrik Svensson, Corporate Development Manager at Sandvik.

Tools like the GibbsCAM Copilot allow new team members to ask questions and get answers directly from an AI assistant, helping them learn faster and reducing the need for constant supervision.

“We are not just growing in size. We are growing with technology,” says Peter. “AI is becoming a natural part of how we work.”

Up2Parts gives us the opportunity to upload STEP files and drawings to make drafts of the programming. So maybe I can get 50% of the programming already done when I open the project file. Instead of doing all the basics, I can focus on the more difficult operations and optimizations.

Improving sustainability through better processes

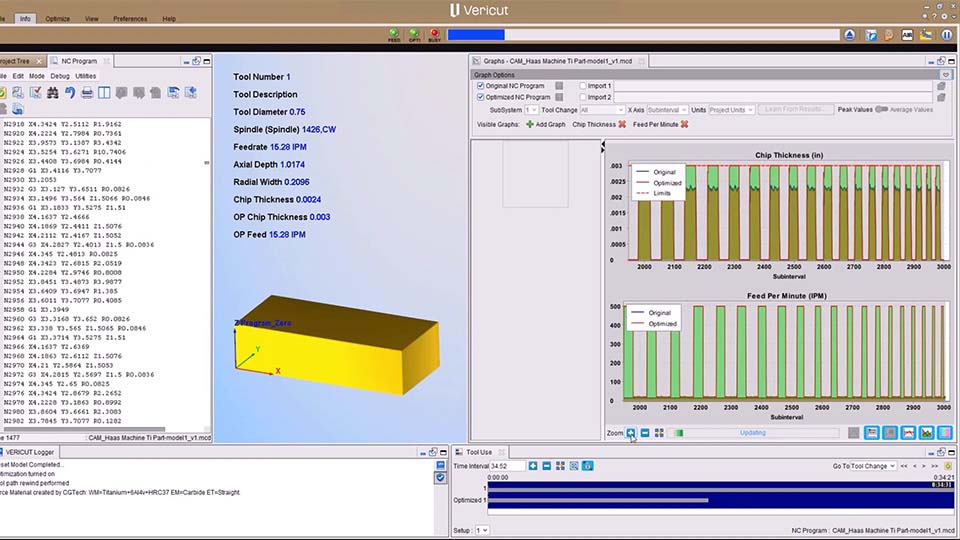

Wallåkra has also taken steps to reduce its environmental impact. One example is the use of Vericut Optimizer, a tool that helps improve machining processes. By analyzing cutting forces and tool paths, the software helps reduce cycle times by up to 25 percent.

“Shorter cycle times mean tools last longer, machines use less energy, and we can produce more parts in the same amount of time,” says Peter. “This could help us very much in the future.”

Wallåkra has also installed energy sensors and monitoring software across its operations. These tools provide real-time data on energy use, helping the company identify areas for improvement and make more informed decisions.

A practical example of modern manufacturing

Wallåkra’s collaboration with Sandvik has supported their efforts to become more efficient and sustainable. Their story shows that even smaller companies can benefit from digital tools and thoughtful planning.

“They are not doing sustainability because they have to. They see the business value,” says Jenny Hörnlund, Head of Sustainable Manufacturing at Sandvik. “Wallåkra is a perfect example of how we want to support our customers. We want to help them become more efficient, more productive, and more sustainable.”

When we’re are ready to post the program, we still find parts of the program that are not really perfect and that’s where we use Vericut Optimizer. We were able to get around 20 to 25% on cycle time reduction. That means the tool will last longer and we’re able to make more parts in the same time.

Key solutions in use:

GibbsCAM:

For over 14 years, Wallåkra has relied on this CAM software to simplify programming and make it accessible for all operators. Even new employees quickly grasp its basics, making production smoother and more efficient.

Up2Parts autoCAM:

This AI-based CAM automation tool, seamlessly integrated with GibbsCAM, automates routine programming tasks. It generates milling programs within minutes, offers smart recommendations for setups, and frees skilled employees from repetitive work. Wallåkra is an early adopter, working closely with Sandvik and up2parts to share insights and success stories from their digital journey.

Vericut Optimizer

By analysing cutting forces and tool paths, this tool helps reduce cycle times by up to 25%, saving energy and extending tool life. Wallåkra also uses energy sensors and monitoring software to track and improve energy use in real time.