Wilson Tool accelerates custom part production with GibbsCAM automation

Download Article PDFWilson Tool International, headquartered in Minnesota with seven global manufacturing sites and hundreds of employees, is a leading provider of precision tooling solutions. Serving industries such as sheet metal fabrication, nutraceuticals, pharmaceuticals, and HVAC, the company is known for solving complex production challenges with innovative technologies.

One of the key enablers of Wilson Tool’s success is its strategic use of GibbsCAM software—particularly its macro capabilities—to automate and standardize programming across a diverse range of machines and technologies.

If you have to run 100 different parts in a day, those used to have to be programmed one by one. Now those can be programmed pretty much automatically and we’re off to the races.

The Challenge of Customization at Scale

Wilson Tool’s product portfolio is anything but standard. While the company does produce punches, dies, and supporting hardware, the vast majority of its parts are customized to meet specific customer requirements. This high level of customization presents a unique challenge: how to maintain speed, efficiency, and affordability when nearly every part requires a unique program.

Jason Esch, Senior Manager of Operations, explains, “We have very few ‘stock’ parts. Most are slightly modified to meet customer demand. That means we need a programming system that can adapt quickly and automatically.”

Before adopting GibbsCAM, Wilson Tool relied heavily on handwritten macros and conversational machine controls. While functional, these methods were time-consuming and limited in scalability. The company also used multiple CAM systems, which created inefficiencies and training burdens across its global operations.

GibbsCAM allowed us to standardize our programming interface, so machinists could move from cell to cell without retraining. And when we change machines, we’re not locked into a vendor—we just repost the program.

A Unified, Scalable CAD Solution

More than a decade ago, Wilson Tool invested in GibbsCAM to unify its programming environment. The decision was driven by the need for a system that could work across all machine centers—whether wire EDM, lathe, mill, or multi-task machining—and support a wide range of manufacturers including Mazak, Haas, Mori, Toyoda, and others.

“GibbsCAM was easy to use and worked on all machines,” says Esch. “It allowed us to standardize our programming interface, so machinists could move from cell to cell without retraining. And when we change machines, we’re not locked into a vendor—we just repost the program.”

Today, Wilson Tool uses GibbsCAM for milling, turning, multi-task machining, probing/inspection, and EDM. The software drives nearly all of the company’s equipment, including those used in R&D and prototyping.

Automated Programming with Macros

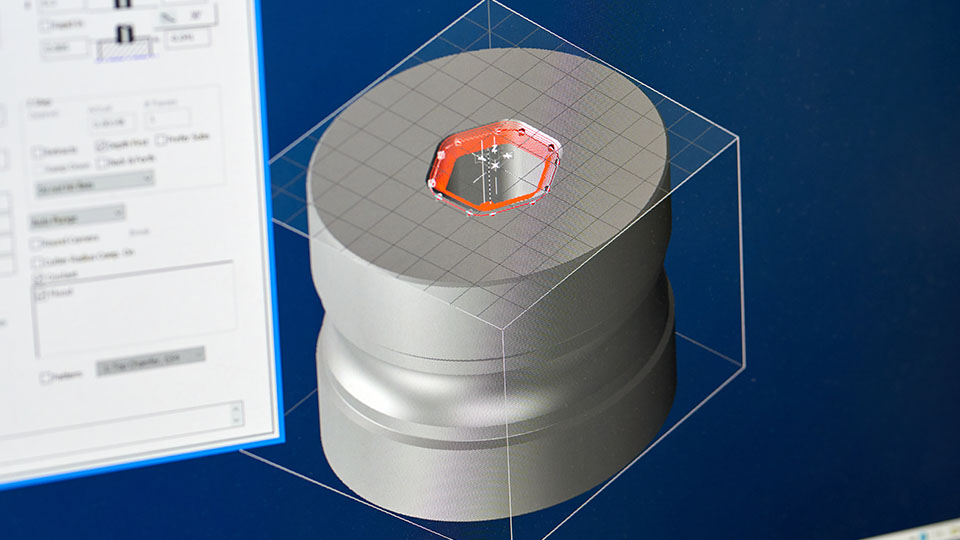

Wilson Tool uses macros for tasks such as:

- Scan-and-complete macros: These automatically post programs based on ERP data.

- Interactive macros: These ask questions to guide the completion of the program.

- Surface-selection macros: These prompt users to select surfaces and then complete the program.

A standout example is the tablet tool die area, where a macro works in tandem with a scan tool to pull order data from the ERP system and generate a complete toolpath. The macro even drives probing cycles, ensuring precision and consistency. This process runs on a Haas mill—a common machine—making it accessible and replicable across the shop floor.

Mark Scanlon, a project programmer at Wilson Tool, notes, “I’ve used similar applications, but GibbsCAM is very user-friendly. The macro capabilities help me train machinists and support wire EDM, mill, and lathe processes.”

Streamlined from Quoting to Shipping

Wilson Tool’s workflow begins with quoting via its ERP system. If customer design work is needed, the project moves to SolidWorks users. Once the design is finalized, GibbsCAM takes over on the shop floor. In some cases, machinists simply scan a barcode and GibbsCAM generates the program automatically. For more complex 5-axis parts, dedicated programmers step in.

After machining, the product is shipped—often the same day the program was created. This level of agility is critical, as Wilson Tool brings out new products daily.

The benefits of GibbsCAM are both operational and financial. By automating programming, Wilson Tool has reduced the amount of time spent on routine tasks—freeing up the programmers for more strategic work.

There are other measurable benefits as well:

- Cycle time reduction: Advanced toolpaths cut down machining time compared to traditional conversational programs.

- Process control: GibbsCAM ensures consistent quality and eliminates overages.

- Training and support: Online resources and on-site classes help staff stay proficient and productive.

Esch emphasizes, “GibbsCAM helps us get the best out of our machine tools. Whether it’s toolpath integration or customized tooling, it allows us to machine special components efficiently.”

“For us, it’s really important to have a system that works across machines, locations, and technologies,” says Esch. “If you have to run 100 different parts in a day, those used to be programmed one by one. Now they can be programmed automatically, and we’re off to the races.”

Growth and Scalability

As Wilson Tool continues to grow and innovate, GibbsCAM remains a cornerstone of its manufacturing strategy. The software’s flexibility allows the company to shift parts between technologies—such as moving a component from a lathe to a mill—to optimize production.

Wilson Tool International’s use of GibbsCAM showcases how automation and standardization can transform custom manufacturing. By leveraging macros and a unified programming environment, the company has achieved faster turnaround times, reduced costs, and improved quality—all while maintaining the flexibility needed to serve a diverse customer base.