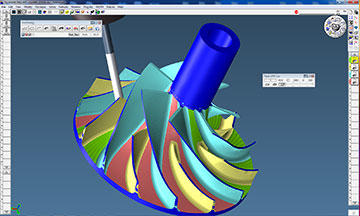

GibbsCAM MultiBlade simplifies the five-axis interface presented to the user, eliminating several model-preparation steps, and automating several programming steps. An impeller with single splitter is shown here in GibsCAM Cut Part Rendering. ABEN Machine got its start in 1998 when Esdras Giron, vice president of engineering and manufacturing, Nabeel Saoud Ph.D., president, and two other partners rented a 1,000-square-foot space that housed a Yang three-axis CNC with a licensed seat of GibbsCAM. As the company grew and began to develop a good reputation for solving manufacturing problems, it moved to different facilities.Its current 6,000-square-foot facility in Canoga Park, Calif. includes seven CNC mills, six CNC lathes and assorted support equipment used primarily to make mechanical components and circuitry housings for first-tier aerospace and microwave telecommunications suppliers. ABEN has become more than just a job shop—it takes projects at the concept stage, makes prototypes, and helps its customers develop and engineer projects. The company employs 17 people, running a full day shift and a partial night shift.

Last June, ABEN added three machines and a trunnion for a Haas VF-4, partially in preparation to help a long-term friend with a job machining prototype impellers for natural gas powered turbine engines. To make the parts and keep costs low, the shop acquired an economical five-axis software. However, the software was not sufficiently intuitive for even an experienced CNC programmer to understand. With a lack of support from the manufacturer/publisher and only very basic training available, the company needed to find another five-axis software solution.

Here are three stages of an aluminum impeller, with the finished (polished) part in front, a matching blank at center right and an unpolished impeller in back. Already familiar with GibbsCAM software, ABEN turned to its representative and upgraded the shop’s three-axis wireframe software to solids-based GibbsCAM 5-Axis MultiBlade, a package designed for turbomachinery parts.

MultiBlade is an automating interface option accessible through the Surface Paths drop-down menu within the GibbsCAM five-axis parameters. It uses the underlying five-axis processes and algorithms, but saves a considerable amount of time in programming, the company says, especially for users who do not program and machine bladed parts regularly.

gularly. For example, without MultiBlade, a user would have to go through eight steps of geometric model manipulation just to prepare the model for programming, and then go through multiple screens of parametric settings. By contrast, MultiBlade eliminates all of these tasks because it automatically recognizes part features, eliminates all the five-axis machining variables that are not applicable to turbomachinery parts from the interface and provides easy interaction through just five context-sensitive parameter-entry screens.

With just three partial days of training from the GibbsCAM representative, Mr. Giron was up to date with solids modeling and machining. Even though he had missed the most recent five-axis training session at Gibbs, Mr. Giron was confident that his knowledge of machining and the representative’s knowledge of using five-axis software would enable the two men to figure out MultiBlade together.

“It was easy to figure out,” Mr. Giron says. “We followed a sample and tested the program, made some adjustments to the toolholder rotation angles to prevent collision, and we started machining.”

Each of the natural gas powered turbine engines requires four small impellers, two of aluminum and two of Inconel. While the fiveaxis work was new to Mr. Giron, his greatest challenge was determining the feeds and speeds for the tiny cutting tools needed to reach between the impeller blades and achieve the tiny floor radius. “I broke a lot of tools before I found the right feeds and speeds,” he says.

The aluminum impeller is 1.750 inches in diameter with 0.700-inch blade height. Mr. Giron uses three ball end mills to cut the impeller: 0.093-inch for roughing, 0.078-inch to finish the blades and 0.062- inch to finish the radius. As a result, the final blades are 0.025-inch thick. When the run of aluminum impellers is complete, he will begin with the Inconel, which he expects to take three times as long to machine, although he’ll be able to increase tool diameters to 0.156 inch, 0.093 inch and 0.078 inch.

While the predominant reason for ABEN to implement five-axis machining processes was to take on the impeller application, Mr. Giron began to find other applications in which the software would be beneficial. He quickly discovered that the software enabled other parts to be programmed and machined more efficiently because he could program two rotary axes, lock either or both axes, and have unrestricted control of the tool axis relative to the workpiece.

While ABEN can now machine parts it wasn’t able to take on before five-axis motion, the greater benefit is faster machining and improved part quality using the five-axis software. Many parts that would require multiple setups on different machines can be made in one or two setups, reducing handling time and opportunities for error. Furthermore, using one or two axes strictly for rotation and location, while machining in three axes, enables ABEN to use shorter tools for greater rigidity and improved surface finish.

The move from basic functionality to solids machining using the new software was a major time-reducing leap, Mr. Giron says. “I don’t need to create geometry, and what it does with solids is amazing,” he says. “I only select a pocket or some other feature, and the software just does it. I don’t need to tell it how many degrees to move. It just goes to the location, rotates and machines it.”

In a recent application, ABEN produced a sensor designed to go down 15,000 feet for a supplier of fiber-optic-based seismic monitoring systems for oil and gas companies. The housings are made from metals including aluminum, brass, bronze and 17-4 H1150 stainless steel, and in order to protect the fiber optics, they cannot have sharp corners or edges, Mr. Giron says. The part is 25.5 inches long with two eccentric ODs (4 inches being the larger), and multiple pockets, grooves and holes. The part took about 7 hours to program, but according to Mr. Giron, the five-axis software saved him about 70 percent programming time compared with a similar part he programmed before implementing the new software. It also saved him a lot of machining time—he was able to lock down an axis and machine the part in one shot. “It’s amazing,” he says. “I’m doing five-axis machining, but my scheduled five-axis training is two weeks away.”

Five-axis machining capability has opened the doors to even more work for ABEN. Although it cannot add another machine to its current location due to space, it is confident that its philosophy of little profit from a lot of work, fairness to customers and a reputation for reliability and quality will help as it considers options for expansion.

As seen in the February 2014 MODERN MACHINE SHOP Magazine and Copyright © 2014 by Gardner Business Media, Inc., 6915 Valley Ave., Cincinnati, Ohio 45244-3029

Capristo Automotive has set itself the goal of enhancing luxury sports cars with high-quality accessories and making them even more unique. GibbsCAM was brought on board when the CAM programming of an INDEX G400 YB could not be managed with the existing CAM software.

Northern Maine Community College (NMCC) has implemented a curriculum that equips students with CNC programming skills using GibbsCAM software, allowing students to earn certification within 9 months and achieve a 100% employment rate.

MUT-Tschamber, a mechanical engineering company in Germany, has implemented Sandvik Coromant's PrimeTurning™ technology and GibbsCAM NC programming solution to achieve higher throughput and productivity.

Toolmaker Rieco System Srl achieves greater machining precision and optimized production time with the help of GibbsCAM software.

SAFA GmbH & Co.KG specializes in the machining of non-ferrous metals, particularly brass, and has developed expertise in machining electrode copper for the production of plug contacts for electric vehicles.

Swedish metalworking company AB Larsson & Kjellberg has embraced 6-axis digital CAM, using GibbsCAM software, to efficiently process production parts for a wider base of customers using their Soraluce FR-12000 milling machine.