Gaining Independence and Productivity with a CAM System

Like most people who begin working in a machine shop immediately after high school, Jesse Alvarado started by doing custodial work and deburring parts. In his first few weeks, he became intrigued with machining, and decided he would learn as much as he could. He went to trade school to learn blueprint reading and conventional machining, and showed his boss the parts he was milling and turning in school. His boss tried out Jesse’s capabilities, and with experience, Jesse came to love machining and making parts. He went to school and learned manual G- and Mcode programming, becoming night foreman within a year. Tired of night work, he moved on to another shop where, after a few years, found himself managing the shop, quoting jobs, programming, setting up and machining.

In 1989, Jesse opened shop in his own garage, while continuing his regular job. In 1992, after seven years with his second employer and three years in his garage, Jesse rented a 1,200 ft2 space in Lancaster, California, and opened shop as J&R Machine Works. Outgrowing two spaces within two years, he built a 3,100 ft2 shop which now houses 12 employees, running 14 CNCs and assorted support equipment. He later added a 600 ft2 building for metrology and administrative office space.

Specializing in aerospace work, both commercial and defense – certified under ISO 9001:2008 and AS-9100-C – the shop experienced rapid growth after 9/11/2001. In the latter half of 2002, J&R Machine started quoting defense jobs, and delivering on a 200-piece order. Business quickly escalated, and J&R was asked to quote 20,000 pieces a year, and won the orders. The shop had no idea we would be at war in March, and it was far into the war that Jesse discovered they had been making parts for AIM-9X Sidewinder missiles. Relying on defense, the shop grew to 24 employees and maintained three shifts, six days a week, through 2009. When defense orders dried up, J&R Machine had to fight for survival.

Through that explosive upturn and catastrophic downturn, and various other cycles, Jesse Alvarado did nearly all of the shop’s CNC programming with manual G-code programming. It was only for the infrequent surface machining project that he outsourced programming. In late 2012, he accepted three orders that required surface machining. After a month, one of the contract programmers told him that he couldn’t program the part. With nearly all lead time gone, the shop had no way to program the part. Vowing that he would never get into such a squeeze again, he acquired a seat of GibbsCAM in January, 2013.

He had no time to learn at the normal pace, so he dived into two weeks of training at Gibbs and Associates, in nearby Moorpark – geometry creation, solid model manipulation, solids surfacing, coordinate sys tems for multi-axis machining, and multi-task machining (MTM). “I would spend daytime in classes, and practice what I learned at night,” he adds. “Everything was new, and I wasn’t learning the normal way – regular turning, then regular milling, and then MTM. I had to jump right into the combined turning and milling – not so easy – but once I got going, it all made sense. It was really made for machinists.”

Through those first parts, he relied on his GibbsCAM representative and Gibbs for help. “With their help, I got those three jobs done and out the door, on time, without any problems,” says Jesse. “Whenever I got stuck, I’d call them, and they were there to help me. At the beginning, it was overwhelming, but by the time I had finished those parts, I felt like I had become an expert at solids machining and 3D contouring.”

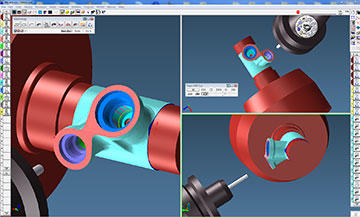

Since that trial by fire a year ago, Jesse has learned a lot more about his CAM system, and has come to rely on many of its features. Cut Part Rendering (CPR), GibbsCAM’s toolpath simulation is one such feature. Jesse uses it to check for gouging, which displays in red; for surface finish, which he inspects by zooming into the rendered part; and because most of the shop’s parts are complex, Jesse often runs CPR with “collision check” turned on.

For anything beyond 3-axis work, Jesse has come to rely heavily on GibbsCAM’s Advanced Coordinate Systems option, which enables creating, orienting and positioning geometry in 3D space.

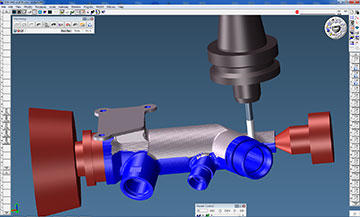

A feature that saves him a lot of time in programming and machining is the ability to “Save as STL.” As Jesse explains, he can save any machined part, any time, in STL (stereo lithography) format, and it becomes his new stock. “That’s how I can machine 5-axis parts in 3-axis,” he adds. “I keep my geometry together with the STL stock body, as I move them around. When I reorient the part to machine another side, GibbsCAM knows exactly where material is left. Then, if I select ‘Material Only’ for machining, I never cut air. This enables everything to blend when I index on the 4th axis and machine in three.”

He also saves the fixtures and special workholding he creates as STL files for his 4-axis machine. When he makes 4-axis parts, he loads his custom made fixturing as tooling, because GibbsCAM will stay away from tooling by whatever distance he specifies.

Saving and reusing is now as common for Jesse. Saving processes – the machining procedures, toolpath pattern, cutting tool, feeds and speeds – saves a lot of time. Special routines, or speeds and feeds in specific materials, or certain types of part features, are good candidates. “I don’t need to recreate a process when I run into one that’s similar,” says Jesse. “I just call it up and use it, or just modify a variable. I have processes saved by material – a folder for titanium, a folder for aluminum, one for 17-4 PH stainless steel, and so on. For some jobs, it can easily save me five hours of programming.”

He enumerates many other features that save time, cost and tooling. After a year, J&R Machine Works has not encountered a part that GibbsCAM can’t handle. The software has cut programming time to a fraction of what it was – in a half hour to an hour, Jesse does jobs that once took six hours – and he can program anything that can be made on 2-axis lathes, 3- and 4-axis mills, or 5- and 7-axis Ganesh MTMs. As important to Jesse Alvarado is not having to risk reliance on outside programmers again.

J&R Machine Works recently started a partial night shift because, once again, the day shift reached full capacity, and there is a foreman ready to go to night shifts when more work comes in. In an effort to diversify and flatten the business cycles, Jesse aims to start offering machining services to the medical industry, although he sees this as a huge challenge for lack of contacts in the industry. He also anticipates getting a 5-axis machining center and a larger multi-tasking machine, but because the shop is full, he needs to determine which of his other machines will need to be sacrificed to accommodate them. In the meantime, Jesse is personally training two of his machinists on GibbsCAM software, hoping to alleviate his own work load.

As Seen in CNC-West April/May 2014 issue