Volumetric Machining Lightens Intake Manifolds

When Brandon Switzer started Switzer Dynamics, he knew the equipment he would need to continue his career in building engines and intake manifolds for drag racing. He had started shops before, the first time right out of high school to support his own drag racing, and after a few years of working solo, he leveraged his experience, expertise and reputation into a partnership in Alabama, followed by a new shop

In February 2012, Switzer moved to Denver, North Carolina, about 25 miles north of Charlotte, where with 17 years’ experience and three employees, he opened his fully equipped shop. Equipment included a dedicated five-axis Haas VF-6TR, a Haas VF-3SS with Jergens table and small trunnion, a seven-axis multitasking Haas DS-30Y, a seat of SOLIDWORKS to model intake manifolds and other components, and a seat of GibbsCAM to program the machines. In addition to the MTM (Multi-Task Machining) and 5-Axis options, Switzer also added VoluMill for GibbsCAM.

The shop’s primary business is building nitrous oxide and induction systems for drag racing. Switzer does custom work and fabricates its own line of intake manifolds by forming and welding sheetmetal. Equipment includes welding and fabrication equipment, a CNC press brake, and support equipment, such as a Behringer saw and a flow bench.

It was in a previous venture that Switzer first began working with CNCs and GibbsCAM software. After he had purchased machine tools and software, he spent a few days with his GibbsCAM representative getting started with CNC machining and programming. When he subsequently acquired the GibbsCAM 5-Axis and MTM software, he decided to learn it on his own. He struggled through his learning process, but it was the way he wanted to learn, and he’s now confident with both software and machines.

Instead of programming conventionally with two to four passes of 1/4” to 1/8” depth, Switzer programs a single pass at full 1/2” depth with GibbsCAM VoluMill, which generates an efficient toolpath with a smooth pattern that Switzer leaves as the surface finish to demonstrate workmanship.

Opening Switzer Dynamics with all new equipment at once was a huge effort, because Switzer wanted to know how to run everything, and he wanted everyone to know as much as possible. Although each Switzer employee has an area of expertise, Switzer has taught all of them to run the CNC machines. This way, when the shop needs to keep production running 24 hours a day, for days at a time, everybody can take turns at extra shifts. This happens regularly, because the shop takes on production machining work to keep its five-axis and seven-axis machines busy.

Switzer believes that trial-and-error is a great teacher, and that he learns a lot by finding the limitations of processes and machines. To that end, he taught himself the use of the milling capabilities provided by the Y axis of his seven-axis Haas and how to program its milling functions with GibbsCAM MTM software. As a learning exercise, he programmed a buckle he was making for Simpson Performance Products (New Braunfels, TX), the company known for its racing harnesses and safety equipment, for machining on the MTM. The part is made of stainless steel, has pockets machined through the part, and has to have all edges radiused so that harness straps aren’t cut under load. “You would never run production of this part on that machine, but I wanted to see if it could be done,” said Switzer, “and I used GibbsCAM VoluMill, to see how fast I could make the part.”

Switzer feels that he learned a lot from that exercise, and feels better prepared for jobs that really belong on that machine, which is normally used for running high-volume parts that the shop uses and sells, such as the nozzles used in nitrous oxide systems, and other parts that can be turned, milled and completed in a single setup.

The production run of the Simpson buckle was done on the three-axis mill, using VoluMill for roughing. It was a challenge because it is 3/16" (4.7-mm) thick stainless steel that required a lot of material removal with 1/8" (3.1-mm) end mills. Switzer said that the shop runs carbide end mills on stainless steel hard at 12,000 rpm and that tools work best and last longest at high speeds and feeds with VoluMill. “On other jobs, we cut big pockets in 1018 steel with a 1/2" [12.7-mm] end mill, at 12,000 rpm and 300 ipm [7.6 m/min], and we get tool life that is easily five times—up to ten times—what it is with conventional milling,” he said.

Traditionally, roughing toolpaths are generated as parallel offsets with sharp corners and transitions, which require stops, starts and variable speeds to prevent tool breakage, reduce tool wear, and avoid excessive loading and tool dwell. In contrast, VoluMill develops toolpaths optimized for volumetric material removal, using continuous tangential motion, specialized contour ramping and adaptive feed rates to achieve the highest feeds and speeds possible. By leveling tool load, maintaining constant machine-tool motion and using highspeed repositioning, the software produces more efficient toolpaths, extends tool life and reduces cycle times significantly.

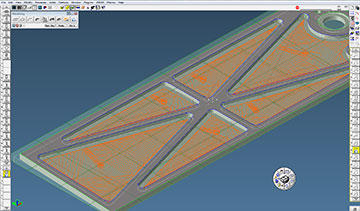

A fuel injection manifold that Switzer Dynamics makes for ReherMorrison Racing Engines (Arlington, TX) that was previously made with sheet metal fabrication illustrates the capability of VoluMill. The deepest cut they make for three-axis manifold machining is 1" (25.4 mm), although most of the pockets on valleys and flanges are 1/2" deep. Instead of programming conventionally with two to four passes of 1/4 to 1/8" (6.3–3.1-mm), Switzer programs a single pass at full depth and full speed for everything, relying on VoluMill to generate a smooth toolpath.

Although VoluMill has tables of suggested parameters, feeds and speeds, Switzer does everything based on chip load, running at maximum spindle speed and maximum feed rate. “I enter the tool diameter, the number of flutes, and my desired chip load per tooth, and VoluMill does the rest,” said Switzer. “It’s easy, and it’s really fast.”

Switzer said that a programmer or machinist who is new to VoluMill for GibbsCAM may not understand some of the variables, so he encourages experimentation. “It doesn’t take long to figure out what tools can do, what ramp rates work best for a tool’s geometry. VoluMill doesn’t need to know everything. You just tell it a few things, and it does the rest. You don’t have to worry about it squeaking a tool in a corner, or doing something bad. It’s going to be perfect.”

The shop used to make intake runners by hand-rolling sheetmetal or by using radiused dies in a press brake, then welding the seam to close them. They would then build the whole manifold, mount it on a manual mill, and plunge mill the holes in the runners to weld the bungs into them.

Now, using the five-axis mill, they make the entire runner from aluminum billet, with bungs already on it, ready to receive the nozzles, then weld the runners to the flange, and weld the plenum on the assembly. The runner walls are made to be 0.090" (2.2-mm) thick, to make runners as light as possible, so there is massive material removal. Still, making the runners from billet is far more efficient than making them by hand. For a production run, the shop usually makes eight manifolds, requiring 64 runners. Machining the runners, instead of making them from sheetmetal, easily saves 75% of the time, and the shop has removed most of the labor by eliminating welding and manual machining. Furthermore, they’ve eliminated needing bungs, because those are now built in.

To emphasize the quality of machining, the shop leaves the toolpath as the finish on all machined parts for the manifolds, whether it is a VoluMill toolpath or a five-axis toolpath. “When I see something polished, I look for the defects the manufacturer is covering up,” Switzer said. “When somebody sees the VoluMill pattern inside the pockets of our parts, they can tell we have good programming software, and I like showing the tool marks because it shows the quality of the work. There’s no reason to hide that.”