With the economy barely showing signs of recovery and the demand for goods and services still depressed, one could wonder about the reasoning behind starting a manufacturing business, and probably find no encouragement. Not so for Paul Beckwith, founder of TraTek Inc. (Noblesville, IN). Beckwith claims to have no secret formula for starting a specialized machining operation in a difficult economy, but he has clear advantages.

With decades of making medical devices at a company he built to nearly 100 employees, Beckwith has a wealth of experience. He sold that company, never dreaming he’d return to machining until he awakened one day to find that what he loved to do was missing. “I was out of the business, but building an organization is what I do, and what I love. I get a lot of satisfaction from that, and I think I’m pretty good at it.”

So, in June 2010, Beckwith decided to start anew. Knowing what he needed, he developed a business plan to specialize in making implantable devices and surgical instruments for the medical industry, and began its execution. “When you enter the medical industry, you don’t just open your doors, because without ISO 13485 certification, nobody will talk to you,” explains Beckwith. “You have to have processes in place, with the ability to document repeatability and part traceability. I wanted to make sure I did this right and had everything set up correctly.”

In November 2010, five months from the decisive day, TraTek opened for business in a 4000 ft2 (372-m2) space, with systems and processes ready to go.

Beckwith began with a lesson learned and honed throughout his career: hire good people. “It was having the right people that gave us a great start-up advantage,” he says. “We hired an ISO 13485 expert, who was, previously, an ISO auditor. He just nailed everything. The auditor credited us with one of the best first audits he'd ever conducted.”

Shaun Smyser, who was hired as TraTek’s engineering manager, came to TraTek with seven years’ experience in medical machining, and expertise in five-axis programming and machining. Smyser would quickly help build and implement the systems to support ISO compliance. TraTek does its own heat-treating, passivation, anodizing, inspection, and finishing. “This provides our customers more predictable deliveries,” says Smyser, “and we don’t need to wait a week for a process, only to discover we have scrap. Doing everything ourselves is mainly to shorten lead time and turn-around for customers, but it also enables us to control the process and reduce cost.”

The technology closest to Smyser, however, is the GibbsCAM CNC programming system, which he learned on his own, using it to program Willemin-Macodel and other five-axis and multi-task machines at his first employer. “Deciding on a CAM system and machines was easy,” he says. “There are many companies that struggle to do what we do, making us think we have an unfair advantage because we never encounter problems. GibbsCAM and Willemin had proved to be an effective and highly efficient combination for all medical parts in my previous employment.”

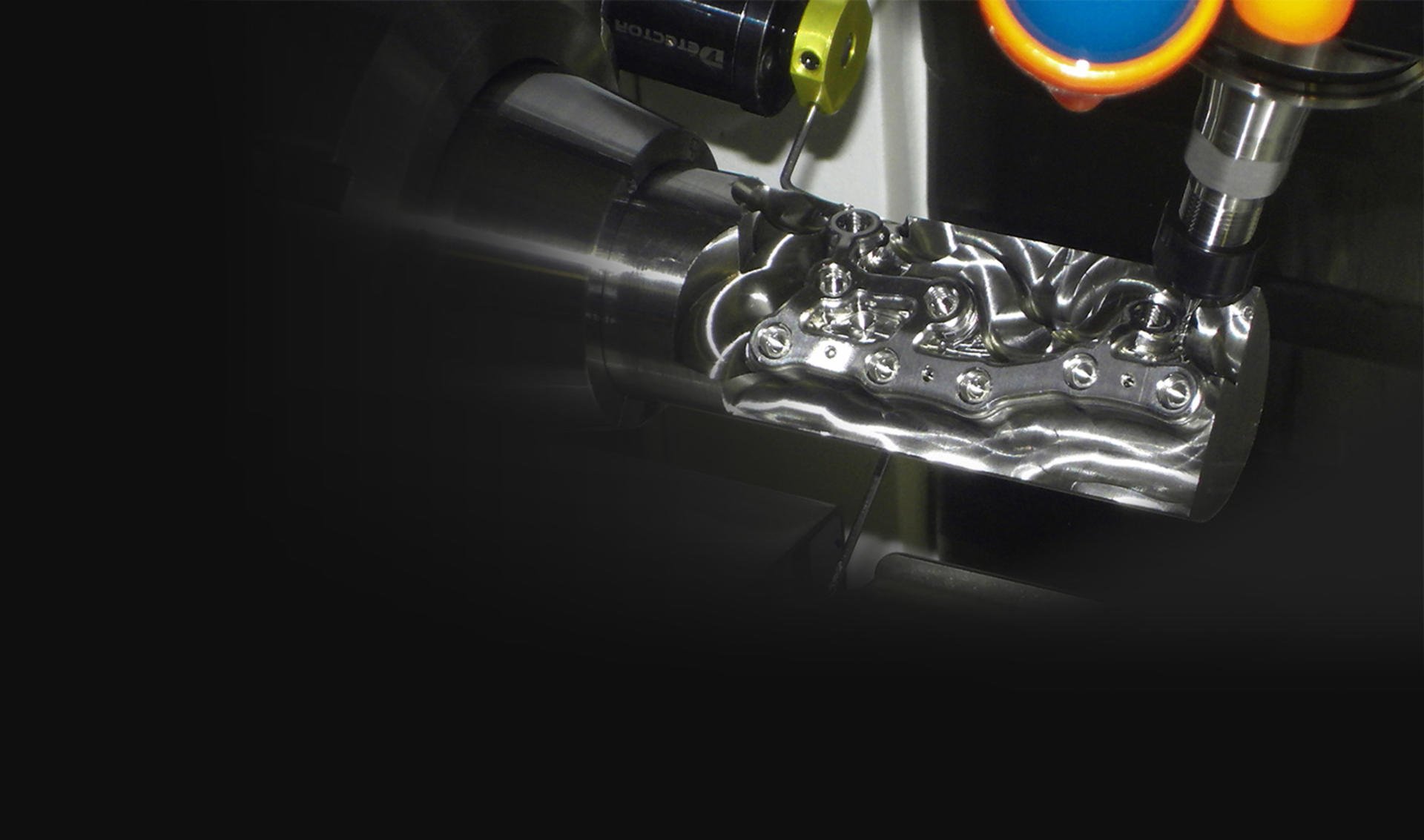

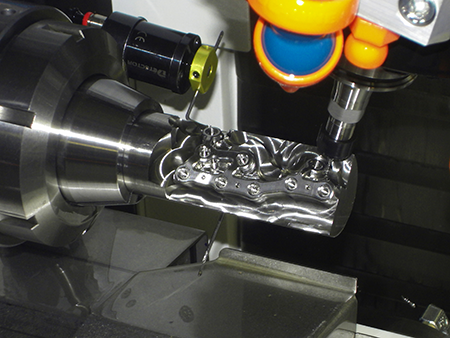

The shop now has four CNC machines, two Willemin-Macodel 408B, one 408MT, and a Citizen L20. Highlighting another advantage of the start-up, Smyser says TraTek has no conventional machines. The company makes everything it needs with CNCs. “We don’t like moving parts from machine to machine for secondary setups and operations, because that introduces inaccuracies and inefficiencies,” he explains. “Our preferred technique is to set up the machine, run the NC program, and make parts, beginning to end, dropping them completed and untouched. It’s one reason we like Willemins.” Beckwith concurs. Having the machines at his previous company, he likes the Willemin people and the support they provide. “Growing from making tiny precision parts for Swiss watches, they are the best machines in the world for small, precision parts.”

TraTek machines parts from PEEK, titanium, stainless, cobalt chrome, and Nitinol to make spinal-fusion cages, components for hip and knee repair, anchors, connectors, plus three TraTek specialties: orthopedic hooks, screws, and plates. The hooks are screwed into bone to align and anchor rods in precise orientation for proper spinal correction and bone regrowth. The screws are of various types and sizes, including those with swiveling, locking heads for precise alignment of implants. The plates, machined from titanium, are used for corrective surgery, where a bone is surgically broken and screwed back together, and for repair of accidentally crushed or broken bones.

Using a representative plate for hand or foot surgery, Smyser describes a typical process for a Willemin 408B, a five-axis simultaneous multi-task machine. It begins with a blueprint or solid CAD model of the part, the largest of which is nearly 1.5 × 2.5" (38–63.5 mm). From a blueprint, everything is modeled in SolidWorks. Smyser prefers SolidWorks or Parasolid formats, these being the cleanest for his programming, relying on GibbsCAM thereafter. “When you get an imperfect model, you don’t want to experience the biggest time waster I’ve seen, struggling with software to make modifications or transfer files, back and forth between CAD and CAM,” he explains. “With GibbsCAM’s modeling, I can modify anything for manufacturability and fix any CAD-model imperfections. It’s easy to use, and saves a lot of time.”

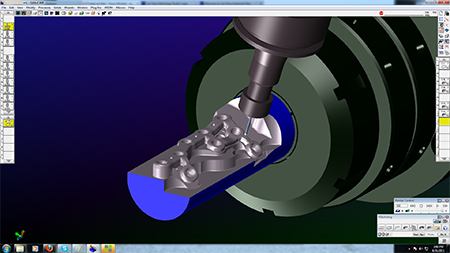

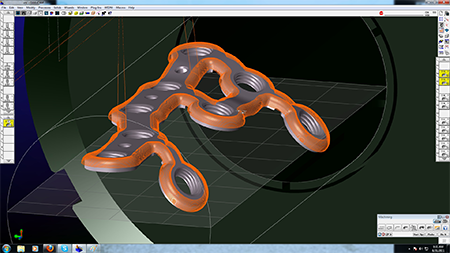

If he had to name a challenge, it would be conceptualizing the machining process and generating toolpath. Smyser begins by opening the CAD model in GibbsCAM, analyzing manufacturability, rotating, and aligning the part for positional fit on the smallest bar stock to eliminate roughing passes during a typical 12 to 50-piece part run for tests and approvals. Plate complexity doesn’t allow working from a datum. There are no flats against vertical walls, but multiple features at various angles. For extremely difficult parts, he uses GibbsCAM-generated models of workholding devices and vise jaws.

Once satisfied with positioning, he selects and extracts geometry for machining, which he says is very easy. Because many of the part features require machining on a tilt—a typical five-axis positioning routine—he does that for each plane with three mouse clicks. “It’s really simple to create coordinate systems to machine at various angles,” he says.

Machining strategies are selected and executed, and toolpath generated ready for verification. In many instances, it’s as simple as that. “We’ve automated much of what we do, saved tool lists, saved speeds and feeds for each tool, for each material, so we don’t have to recreate anything done in the past. I retrieve what I need in GibbsCAM and generate toolpath. We’ve been able to turn around complex parts very quickly.”

Another thing Smyser likes is the ability to do operations out of sequence, intentionally, not from poor planning, doing “risky sections” first, before doing the rest. He usually verifies each operation with GibbsCAM’s Cut Part Rendering, which shows stock and finish as it appears after toolpath removes material. Verification can be done at any time, for any operation, in or out of sequence, or all operations in sequence. “Then I post-process the whole thing and sort the operations afterward. It’s an easy drag-and-drop of an operation tile into a new location. Other systems force you to rerun the whole program with operations in the desired sequence; if you change one operation, you have to rerun and reprocess everything, both with toolpath generation and verification. With GibbsCAM, you can sort and reorganize as much as you want, and you’re ready for the machine in seconds.”

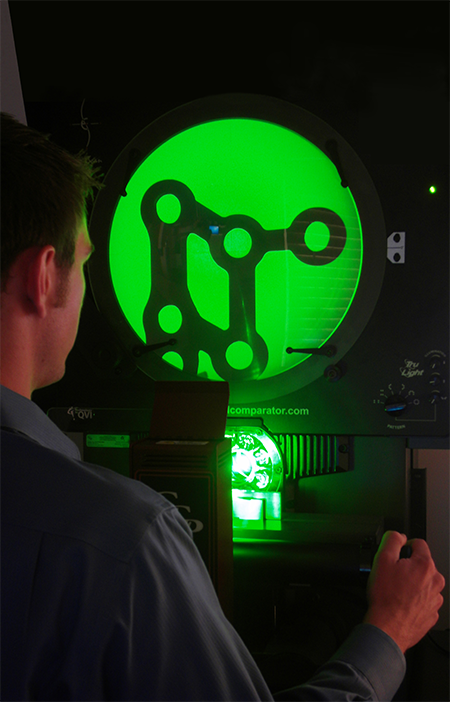

With its competitive advantages, TraTek limits itself to taking customers through the iterative prototype stages, providing short runs for cadaver testing, bend, stress and failure testing, and final FDA approval, which may include submitting all the machining data, the specifications to which the part is made, and documentation of cleaning processes. “It’s difficult work for most shops, but that’s the way we want it,” says Smyser. “We have a huge advantage, controlling everything to provide perfect, fully documented parts in the shortest time possible.”

That doesn’t prevent having an eye toward the future, where TraTek sees expansion into doing the high-production runs customers require after FDA approvals. “One of our biggest advantages is that we are still small, with only nine employees, and we are managing our growth,” Beckwith observes. “We aren’t solidly successful yet, but we’re going to do our best with a good team. I am very careful about the people I hire, and we will not grow fast unless we find the right employees. That’s something I learned in my previous company, and it’s the best advice I can give. Don’t grow faster than your ability to find the right people.”