Rick Denny started working in a shop in 1965, and learned NC programming in 1970. Moving forward, he worked at large and small job shops, in machining, engineering, and management, never straying from NC programming. With experience from shop floor to front office, he launched his own company in 1994, recruiting stepson Mike Andersen as equal partner. A home equity loan funded the start-up, enabling the purchase of a Fadal VMC. “Then we rented enough space from another shop to have two feet on either side of the machine,” says Denny, “and we took the plunge, to create Blue Chip Engineering.”

Initially, Denny worked part time, while Andersen worked full time, gaining the experience that enables him to run the shop today. Within a year, the duo built a rotary axis for the Fadal, and began to build their chip-making arsenal. By 2003, the company included 20 employees and 10 CNCs, including two 5-axis VMCs, one lathe, and a programmable CMM, all housed within their 4,600 square foot facility in Ramsey, Minnesota, just northwest of Minneapolis.

From an 8-inch diameter billet, a CNC lathe formed the inner surface of each hemisphere, roughed the exterior, machined a flange to mate the halves, bored 8 holes on the flange for locating pins to achieve registration between the two identical hemispheres, and tapped 8 holes for 10-24 screws.

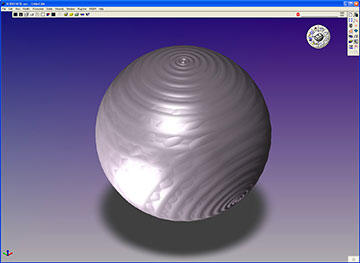

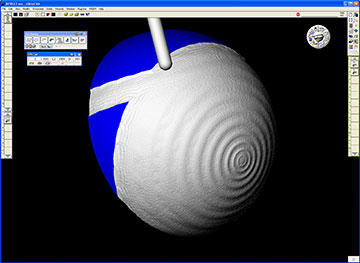

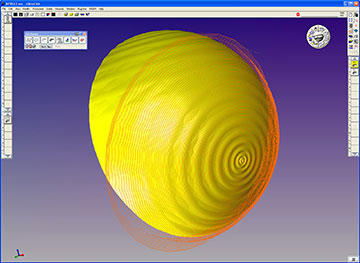

Each part was bolted to a mandril with the threaded holes, and fixtured for surface machining. Because the weight requirement was so restrictive, the wall thickness had to be reduced to .040". Finally, the triple pattern was cut into the surfaces such that the design appeared to be machined as a one-piece sphere, continuous and perfectly matched when the hemispheres were mated. For a good finish, they used a 1/4" poly-crystalline diamond ball end mill and polished the surface to a mirror finish.

Blue Chip made the hemispheres, and sculptor Tom Shannon mounted rare-earth magnets inside, assembling them into spheres, which he floated on magnetic bases of his making to create the sculptures. An .018 diameter, metal cable “tether” centered each sphere above its base to prevent its wandering away from the magnetic field and falling if bumped.

The sculpture was first awarded in 2005, the first of 3 recipients being Bono, the Irish rock star, for his continuing humanitarian work in Africa. Blue Chip also machined the TED awards again for 2006 and 2007. This year the award was given to President Bill Clinton, war photographer James Natwey, and scientist E.O. Wilson.

In having the first sculpture machined by Blue Chip, Shannon learned that he could cut time off his design stage, and has since directed additional work to the shop. He usually sends a sketch, from which Blue Chip develops a CAD model in SolidWorks, returning screen images for review. Then they proceed with any desired design and NC programming iterations, sending GibbsCAM Cut Part Rendering images to Shannon before machining.

Denny says that Blue Chip owes its survival to GibbsCAM and other leading edge technology. “If we hadn't invested in something like GibbsCAM, we would be out of business. GibbsCAM, SolidWorks, 5-axis machines, and our Zeiss solids-programmable CMM will keep us competitive and growing.”

“But we also need to keep employees trained and up to date on the technology,” he adds. “My daughter Paula, for example, is the primary programmer of the Zeiss CMM, uses SolidWorks, and recently completed basic training in GibbsCAM.”

The shop will be machining Shannon’s sculpture for the 2008 thru 2010 TED awards. In the interim, they’ll be working on other Shannon projects and doing difficult machining for other industries. Long past the threat of failure, their wish list includes a return to profit sharing for employees, another Mori-Seiki with 4th and 5th rotary axis, and another seat of GibbsCAM. Apparently, the backrubs can wait.